A quick introduction about ZDHC

ZDHC stands for Zero Discharge of Hazardous Chemicals and is a program that guides the fashion industry toward eliminating harmful chemicals from its global supply chain.

It should be noted that ZDHC is one of the two most important global organizations in the field of sustainability for the fashion industry. In fact, among the companies that join the program, we find many of the brands recognized as the most important and influential in the world.

The ZDHC program also aims to create the foundation for more sustainable production that protects workers, consumers and our planet’s ecosystems.

The strategy is based on the principle of transparency in chemical management using a precautionary and preventive approach, building on a set of shared best practices. That is why it is in constant evolution.

The main goals of the program are:

- eliminate or replace hazardous chemicals

- develop transparent processes to promote safer chemistry

- develop the effective tools, best practices and training to improve chemical management

- develop collaboration with stakeholders to promote transparency about chemicals used/discharged and the application of good practices

The Impact Day 2022 event by ZDHC.

Each year, the results of the ZDHC strategy are carefully reviewed and then presented to member members during an event called Impact Day, which takes place in Amsterdam. In addition to measuring the performance of the year concluded, the event is also designed to set the agenda items for the year to come.

For our industry, this is an extremely important event, which gathers all the high management officials from the various companies to decide on the future sustainability strategies.

This year the event was held on Thursday, June 16, 2022 and as a support of this year’s performance presentation, the ZDHC organization asked three virtuous companies to share their testimonies.

It is much more than an honor for us to be able to say that Cangioli 1859 was one of these three companies. Along with Cangioli 1859’s Italian experience, testimonies from a Chinese company and an Indian company were given.

Cangioli 1859's experience at Impact Day 2022

As a testimonial for the event, our intervention served to bring the experience of Cangioli 1859, supporting the Impact Report covering the year 2021.

Vincenzo Cangioli, President and CEO of Lanificio Cangioli 1859, was interviewed by the ZDHC Communications Team and his video interview was projected during a session of the June 16 event.

Here are the interview excerpts that were shown on video during the event covering 3 main topics:

1) How can the Supplier to Zero programme lead to efficiencies across water, energy and emissions for your business?

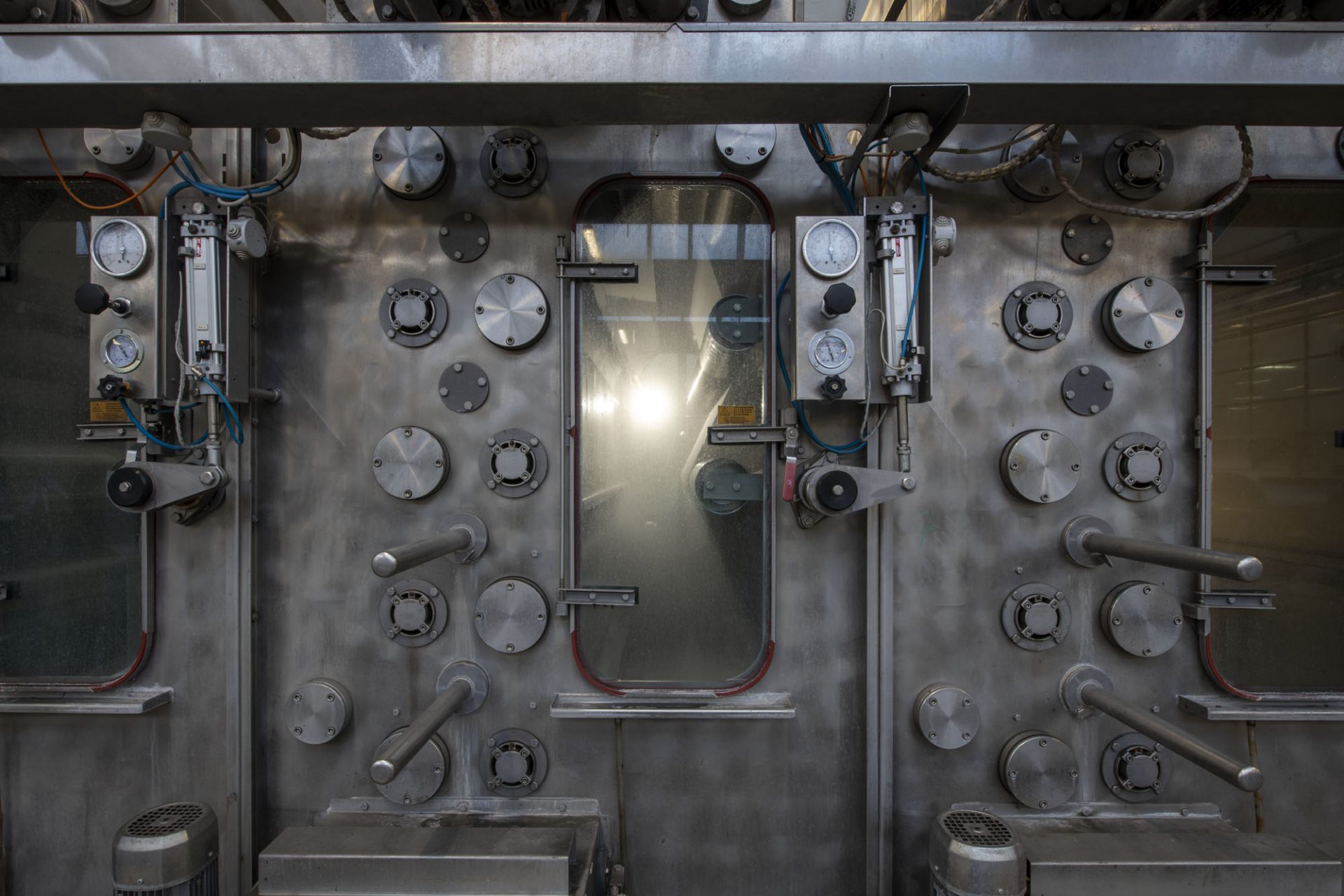

“Energy efficiency has always been a goal in good management practices at Cangioli. The first drive to be at the forefront of innovation in energy efficiency dates back to the mid 1970’s with a then futuristic high efficiency cogeneration pilot plant and since then we have never stopped in our drive at being attentive and innovative.

Adhering to The Supplier to Zero programme gave us a tool to help us proceduralise, and measure the efforts in our energy and water efficiency program. It is a strong “motivator” in helping us define an ambitious roadmap to continuous improvements. The suggested good practices help us prioritize our investment plans and our operational procedures. The use of monitoring systems is crucial in achieving the goals that we set at each step.

We have implemented a sophisticated and capillary energy monitoring system throughout our production departments which gives us the ability to analyse in great detail the energy profile of our processes. This system, for example, identified an opportunity in an otherwise underestimated exhaust steam energy that was being dispersed in the atmosphere and led us to capture and use it to fully heat our offices in the winter and pre-heat water for our hot water processes in the summer.”

2) How are you benefitting from the joint implementation of the Supplier to Zero programme?

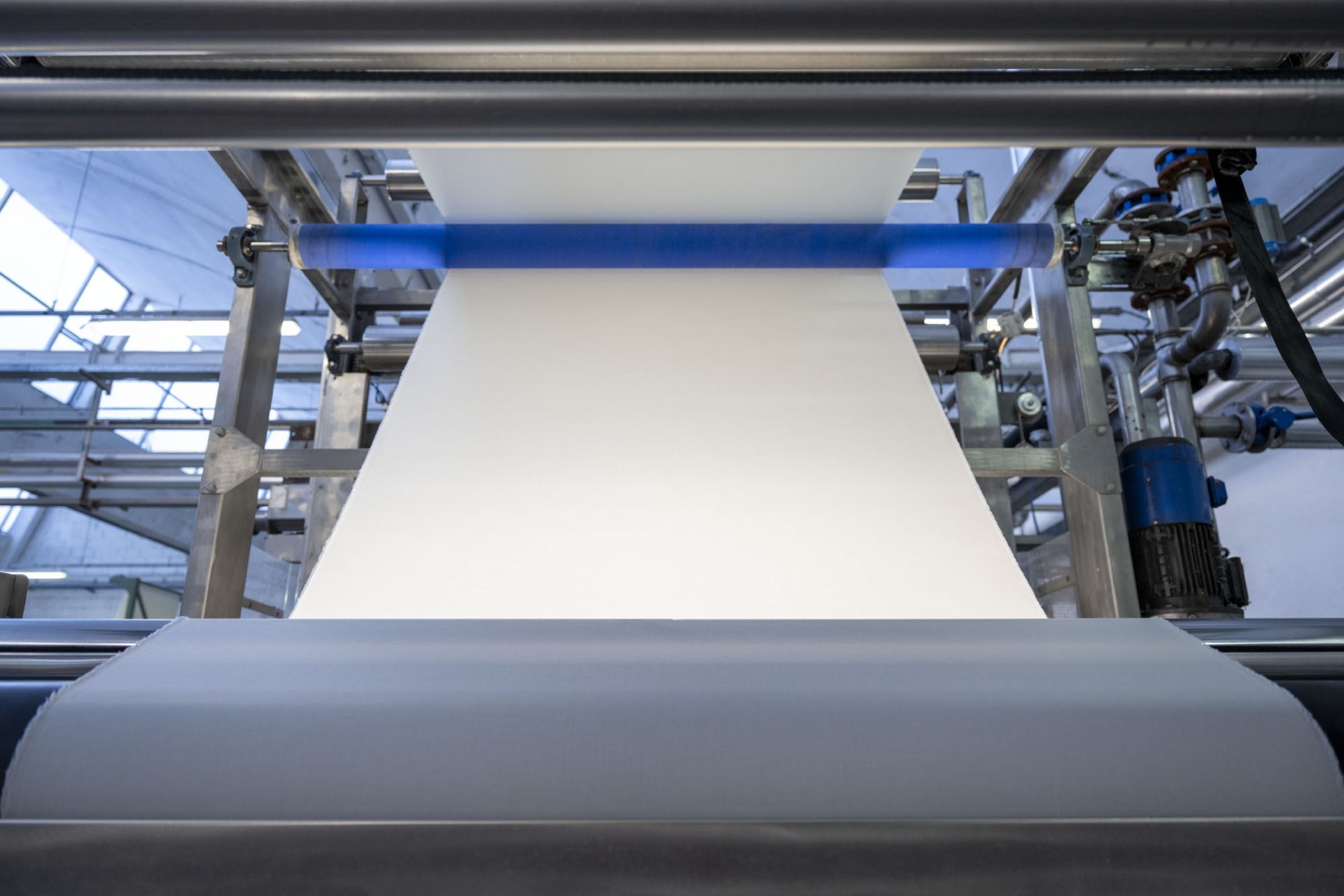

“As a company we embarked on a path to the implementation of a Chemical Management Program that thorough the years has become more and more articulated and ambitious. The Supplier to Zero Program was the indispensable and instrumental tool to define the protocols, objectives and KPI’s that helped us achieve a structured and successful improvement path. The continuous verification of the KPI’s defined in the S2Z help us measure and fine tune our system performance.”

[…] A very important aspect of the implementation of the S2Z Program is the growing transparency between the stakeholders with regards to the procedures being implemented and the resulting data. This growing transparency is crucial in measuring the real improvements in in our joint path to roadmap to zero.

The publication of the obtained results is a strong stimulus for improvement. The challenge of being measured publicly has had the positive impact of giving us a very strong motivation to improve – in our dye and finishing plant Penta-Rif – the compliance of our chemical inventory through the evaluation of new products and the development of new recipes.”

[…] Last but not least a very important aspect is the necessity to give greater weight to traceability. At Cangioli, culturally, we have always had full traceability of raw materials (fibres and yarns) in all our production lots. The S2Z program gave us the new challenge of adding a different dimension to traceability by now having to fully trace the use of each chemical product in all our production lots.Last but not least a very important aspect is the necessity to give greater weight to traceability. At Cangioli, culturally, we have always had full traceability of raw materials (fibres and yarns) in all our production lots. The S2Z program gave us the new challenge of adding a different dimension to traceability by now having to fully trace the use of each chemical product in all our production lots.”

3) How can the introduction of the performance levels help you advance your performance and leadership in terms sustainable chemical management?

“As a company we embarked on a path to the implementation of a Chemical Management Program adhering to the 4sustainability CHEM protocol so we already had familiarity with implementation protocols that measure advances in performance.

[…] The performance level certificate is also crucial as a strong motivator and a well-earned reward for our teams by giving full recognition of all the excellent work that they have carried out in advancing our organization in terms of sustainable chemical management.”

“The gratification was great, but we are aware that there is still a long way to go.”

Impact Day 2022 was a great opportunity for us to demonstrate the results of all our efforts in terms of energy, water and thermal efficiency. But even more, it was the perfect chance to define a common vision on the sustainability strategies for the coming years, which see Human Resources as one of the key points of the Agenda.