Industrial Capacity

Production Process

A constantly evolving vertical industry.

A constantly evolving vertical industry.

We have developed a road map for integrating sustainability strategies and business needs, which has led to the creation of a fully self-sustainable internal production chain.

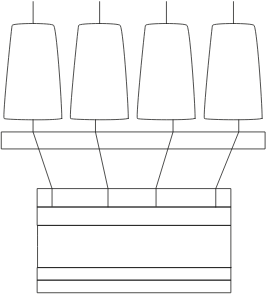

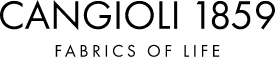

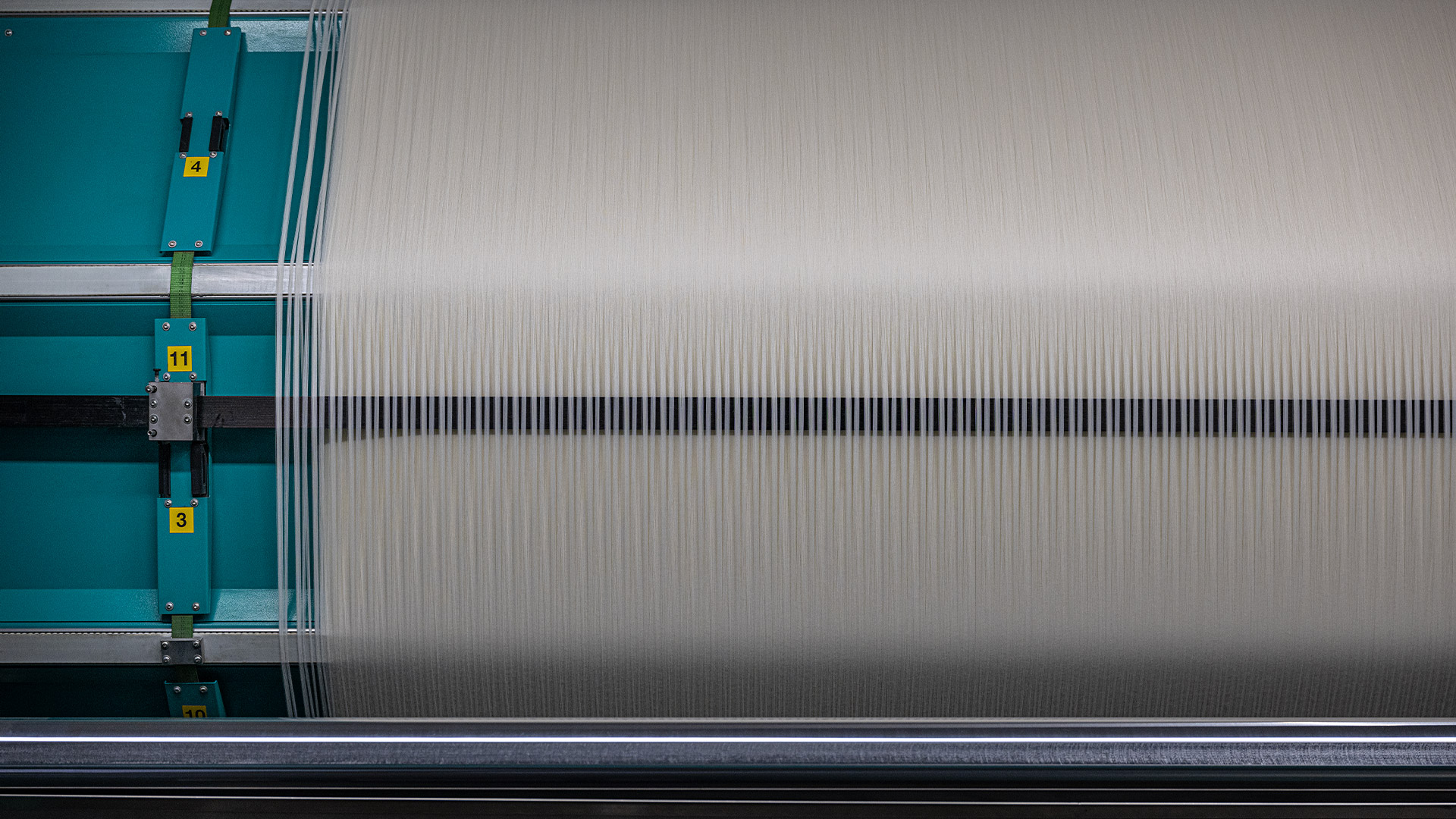

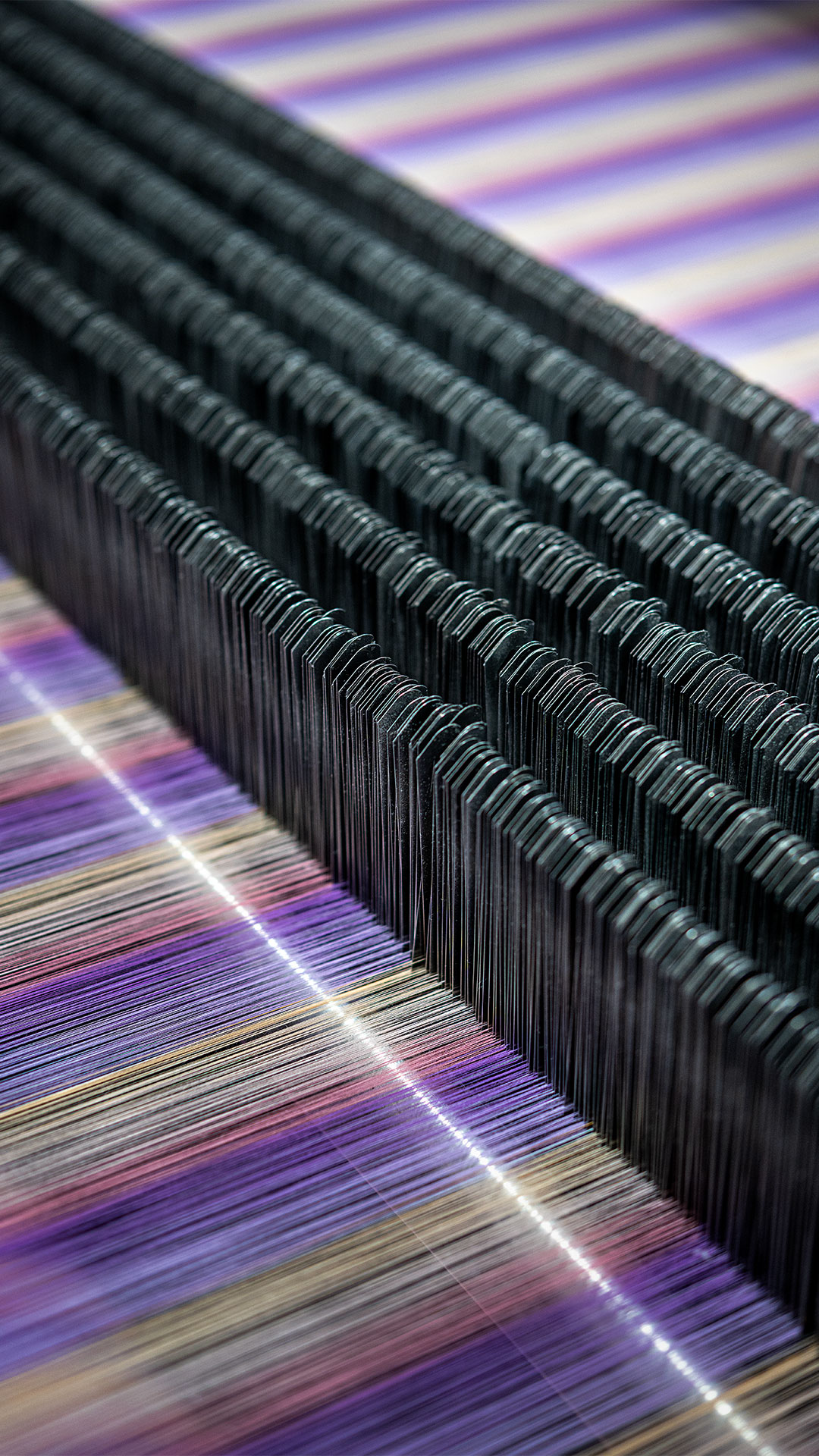

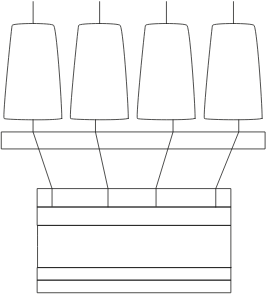

Warping

Perhaps warping is the most symbolic phase. It is the first step in the production process. A crucial moment in which man and machine work together in absolute balance.

On-going quality controls

Strict sustainability standards

2.6K

metres of weaved fabric

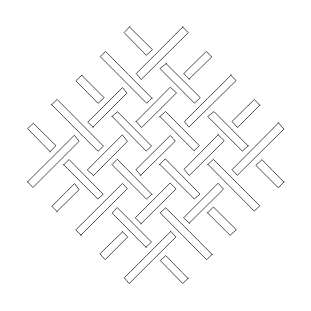

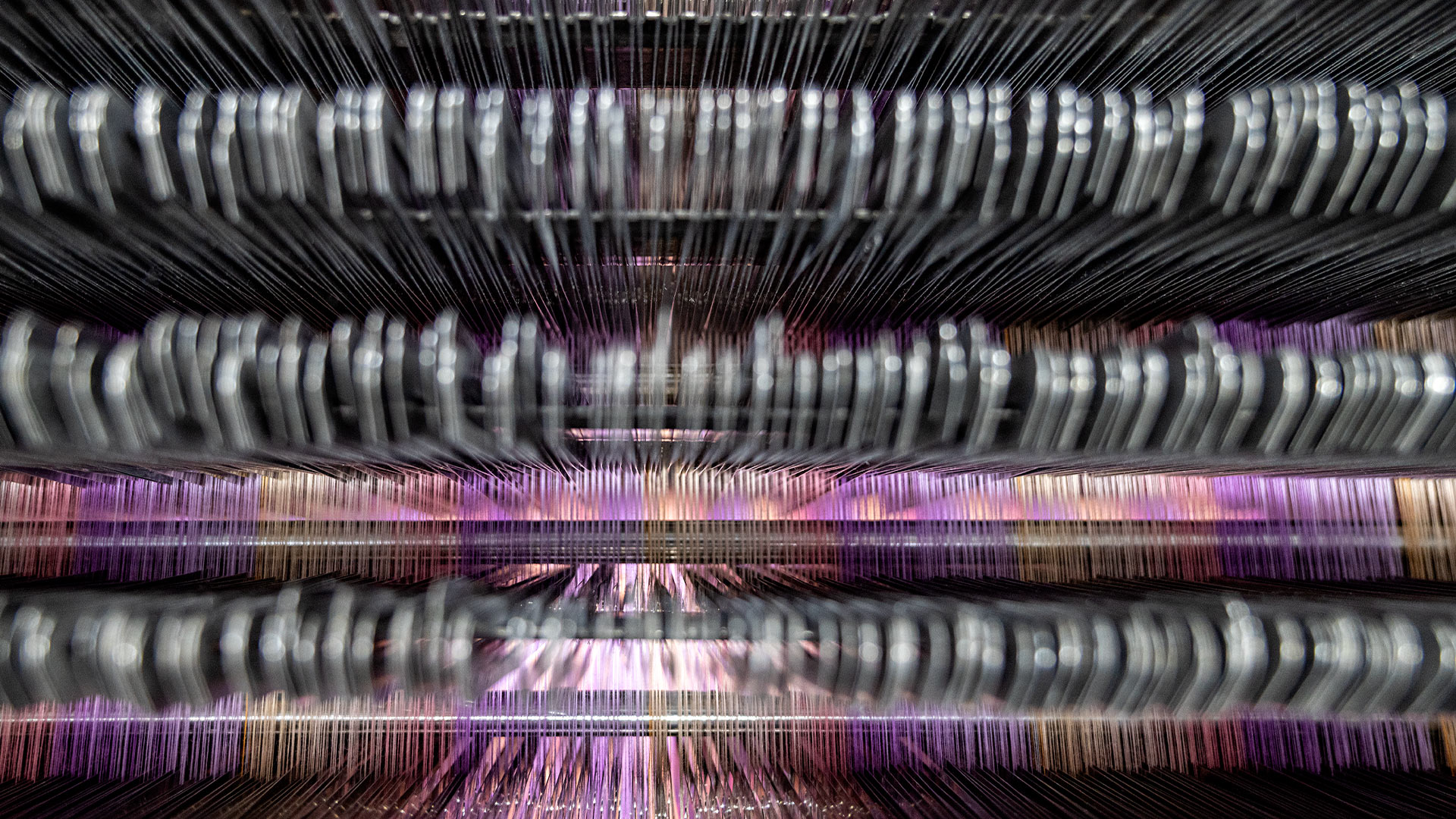

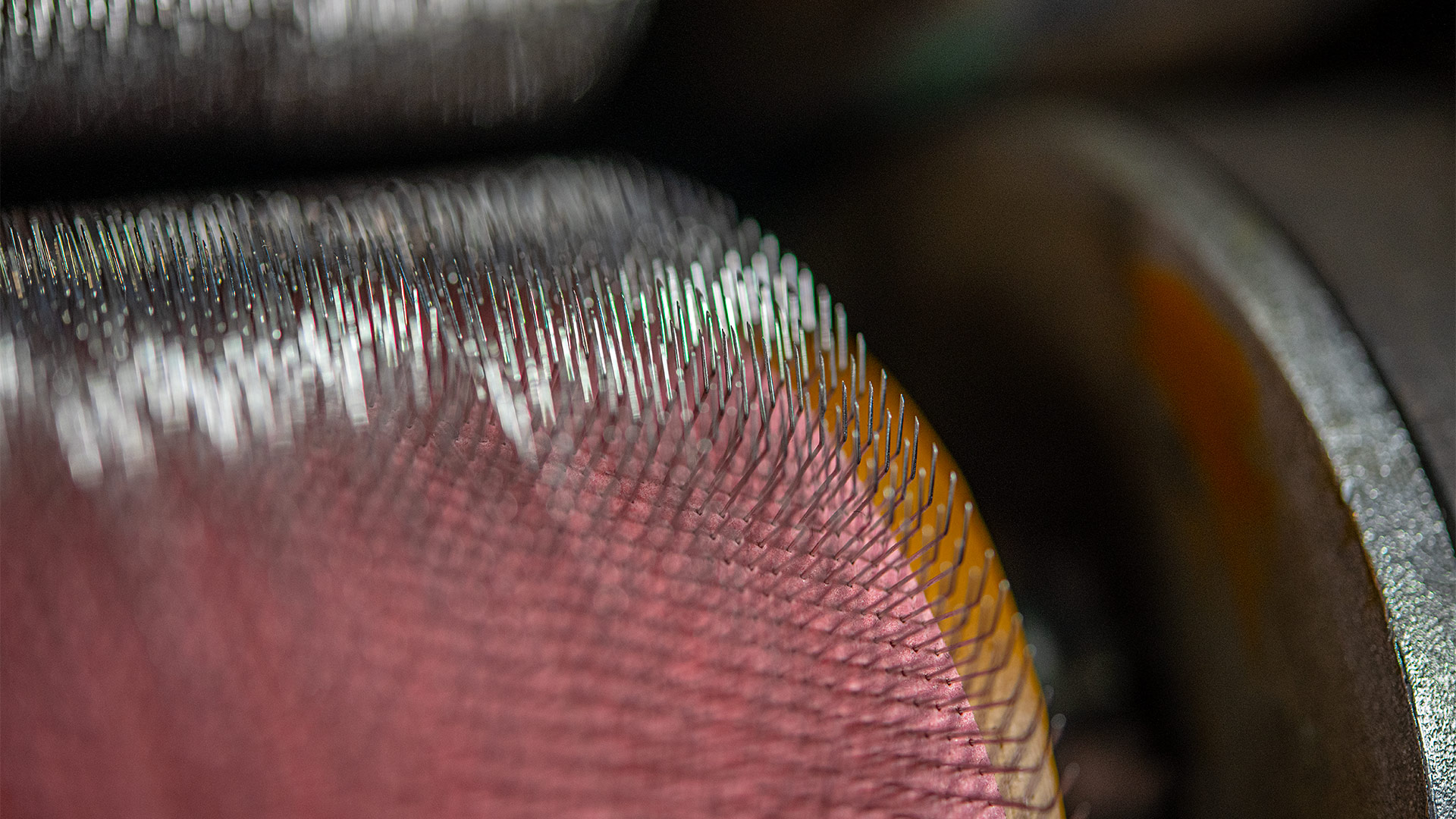

Weaving

With a pool of 42 weaving machines, the entire weaving process is also fully managed in-house. We are able to be weaving at a rate of 9 billion strikes per second.

On-going quality controls

Strict sustainability standards

Dyeing

At the dyeing stage, we submit the fabrics to the most demanding tests so that we can guarantee compliance with the highest quality requirements.

On-going quality controls

Strict sustainability standards

3.3K

Metres of fabric manufactured

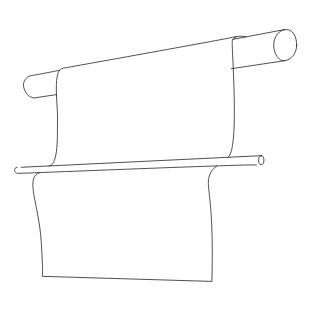

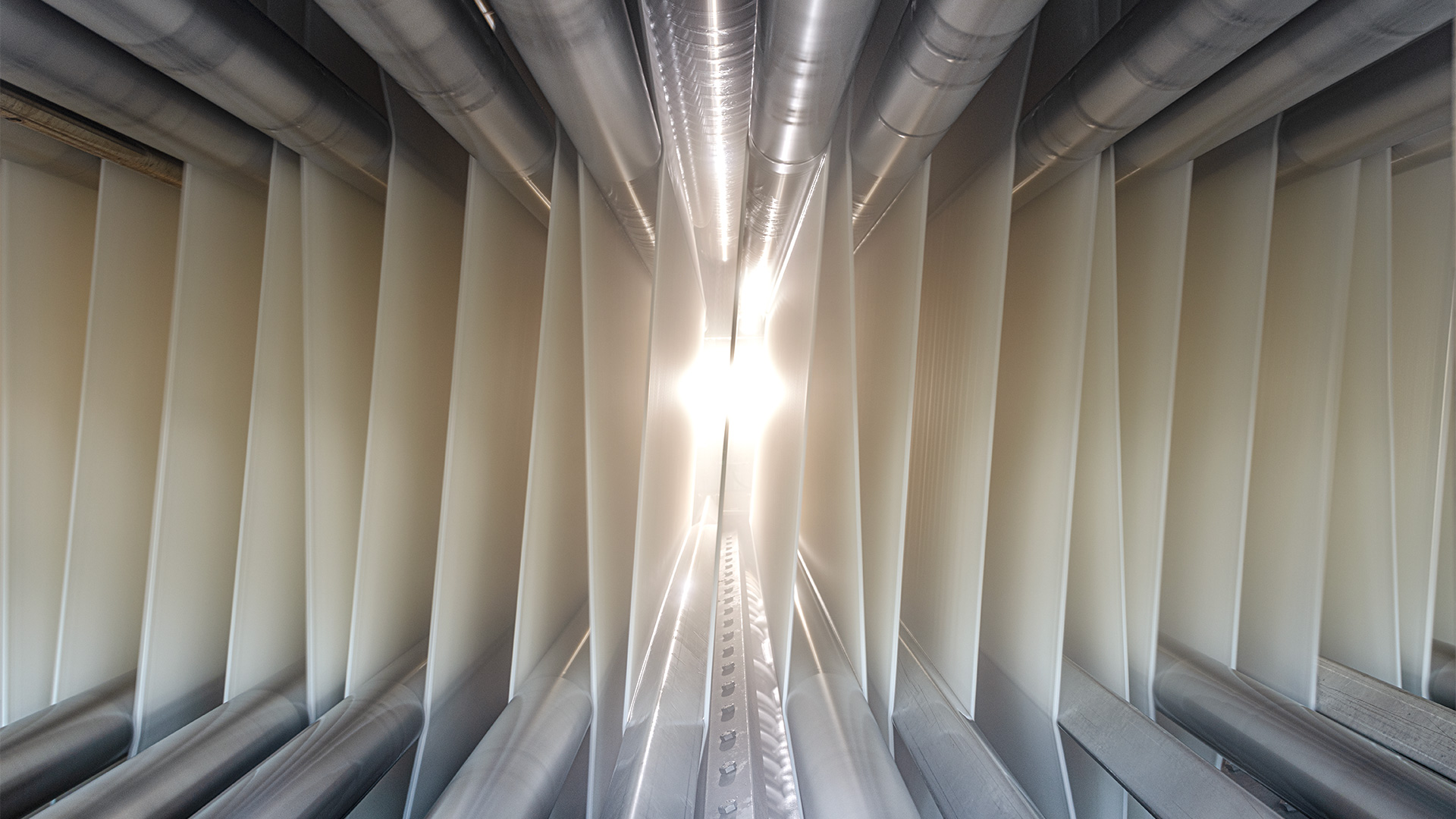

Finishing

Once in the finishing plant, our fabrics are then exposed to a series of treatments aimed at improving multiple characteristics, such as: appearance, texture, properties…

On-going quality controls

Strict sustainability standards

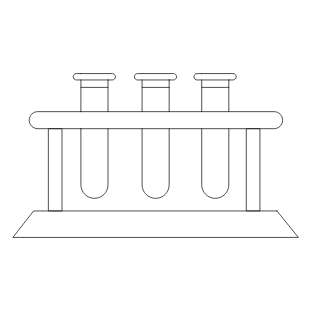

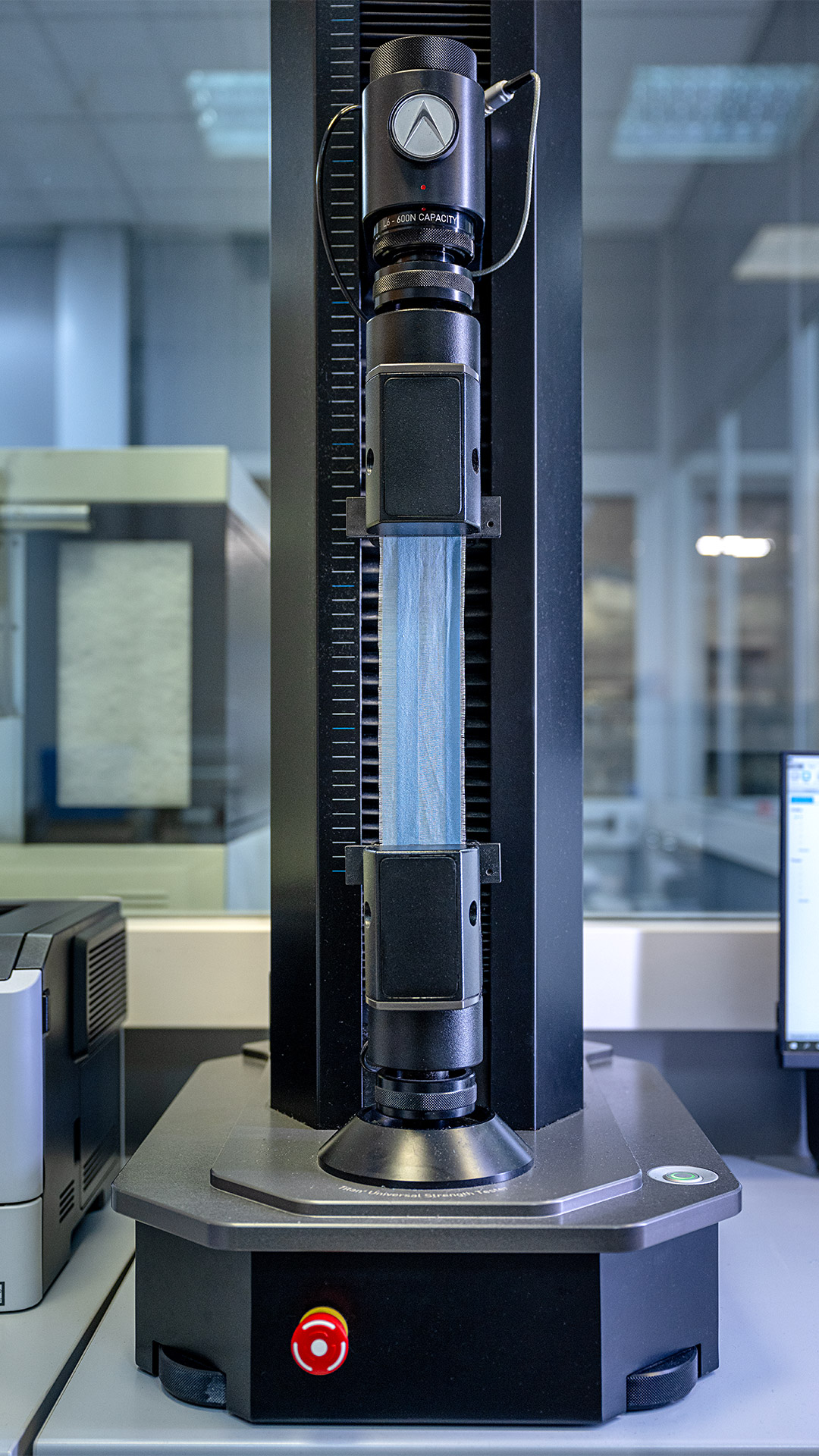

Laboratory

The laboratory is equipped to conduct different types of tests in order to measure objectively the performance of our fabrics and to understand how suitable an article is for a specific use.

On-going quality controls

Strict sustainability standards

We stand for Quality.

Always.

We conduct the most rigorous quality tests on our products throughout the whole production cycle. In the final step, in our characterisation laboratory, we work with the independent Certification Authority Coteco to measure the performance of the finished product.

Physical tests

Including tests for elastic properties, resistance to tearing, abrasion, pilling…

Physical tests

Including tests for elastic properties, resistance to tearing, abrasion, pilling…

Dimensional stability

Defined by water washing, dry cleaning, drying, hot air re-entry tests, etc.

Dimensional stability

Defined by water washing, dry cleaning, drying, hot air re-entry tests, etc.

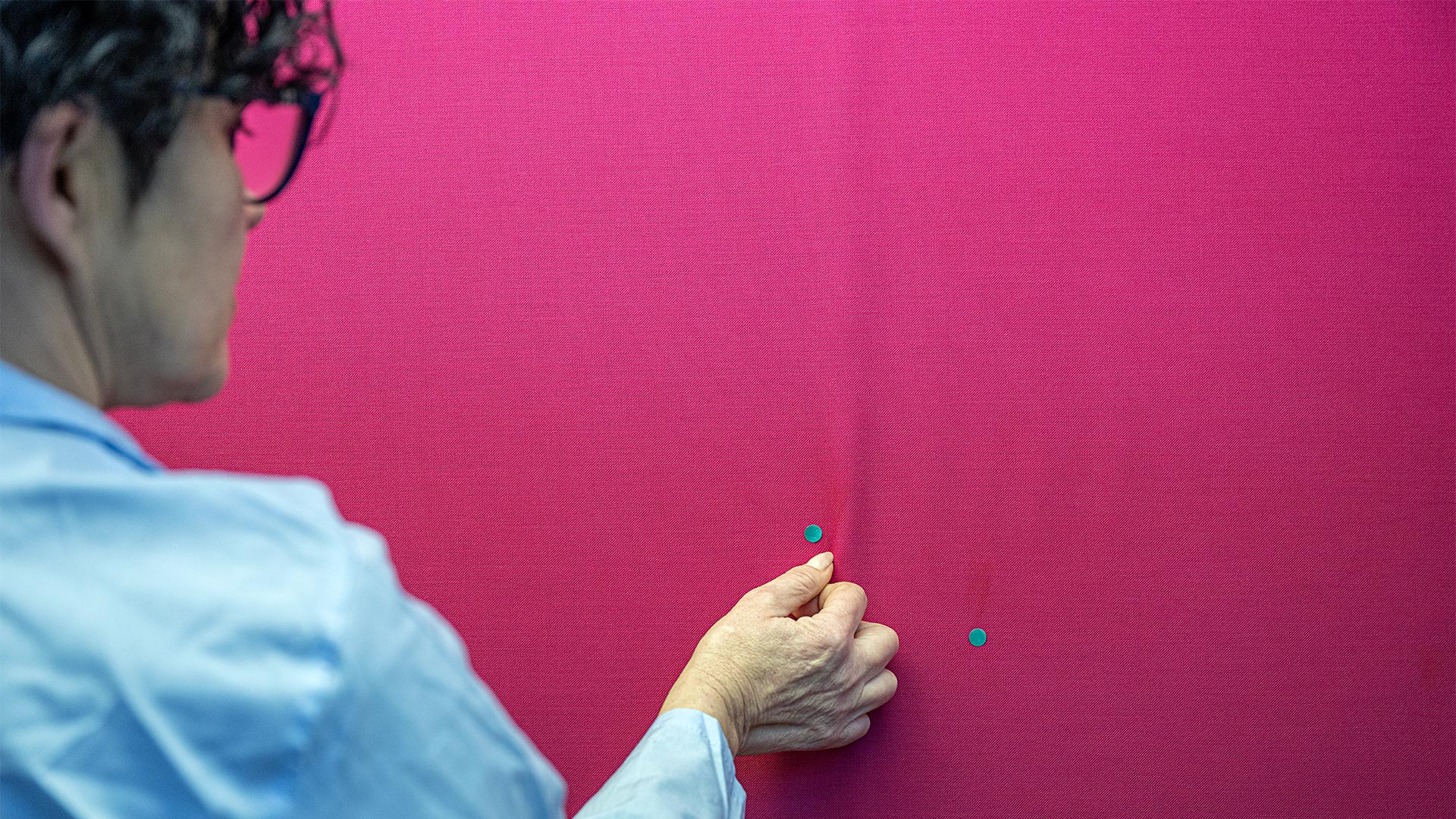

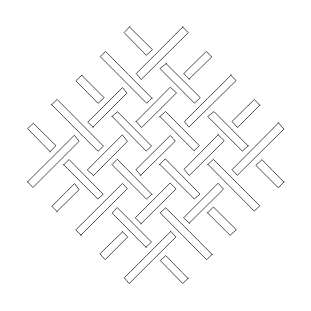

Irregularities

We carry out tight checks for defects, interruptions, crooked textures and pattern’s irregularities.

Irregularities

We carry out tight checks for defects, interruptions, crooked textures and pattern’s irregularities.

Sustainability

is no fantasy.

The values at the heart of our strategy: people and the environment.